Ignition coils are typically very reliable, but like any mechanic or electronic car part, can fail. To understand the range of coil failures, it is important to understand how different coils work as well as how heat fits into the equation. Whether your coil is the older canister type or your vehicle uses a coil-on-plug, coil-per-cylinder or coil-near-plug ignition system, a coil is a transformer consisting of an iron core surrounded by primary and secondary windings. The ratio of turns between the two sets of windings determines the coil's maximum output voltage. When voltage from the vehicle's battery flows through the coil to the spark plug, it ignites the fuel mixture in each cylinder.

Regardless of the type of ignition system, all coils are subjected to heat with the constant surge of power running through them. Over time, this surge of voltage and the subsequent heat generated by the process can break down the insulation between the primary and secondary windings. When a coil-on-plug or coil pack begins to have issues, the performance of the engine will suffer due to the loss of spark in one or more cylinders. A bad coil can produce symptoms such as an engine misfiring, a reduction in miles per gallon, difficulty starting or stalling of the engine when you try to drive away.

Today's vehicles have an ECU that records the sensors readings and logs the faults as well as displays the dashboard's check engine light. For less than twenty dollars, you can purchase an OBD2 code reader that plugs into a 16-pin port located under the driver's side dash. The reader will display one or more code numbers that can be cross-referenced to identify where failures have occurred. In most cases, a failing coil will produce multiple faults but you don't have to worry about deciphering each code. Using an ohmmeter, you or a mechanic can compare the current readings for the primary and secondary windings.

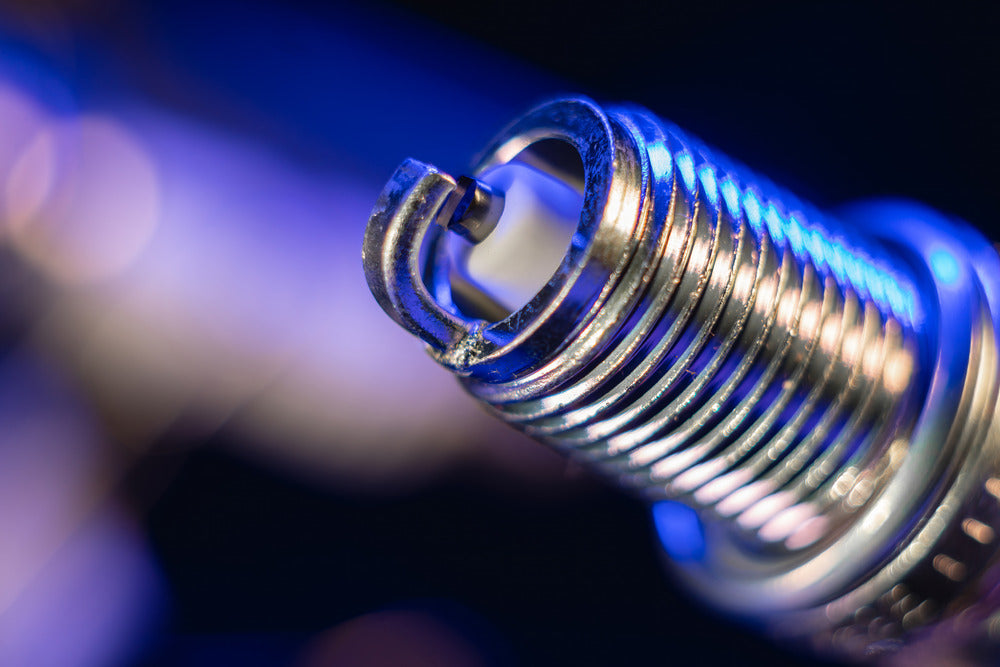

Once you replace the defective ignition coil, erase the codes with OBD2 code reader, crank the engine and see if any of the codes come back. It may be prudent to replace the old ignition wires and install new E3 spark plugs to restore the original spark. All the ignition connectors should be thoroughly cleaned and dielectric grease applied to prevent corrosion and assure a better connection. Just remember, replacement coils must be the same basic type and have the same primary resistance as the original. Using the wrong replacement coil may damage other ignition components or cause the new coil to fail prematurely.